Golden Words or Phrases That Super Scholar Should Master

连接法兰 fitting flange

定位鞘 fitting pin

垫板 fitting plate

挠度 deflection

精制的,完工的 finished

精制螺栓finished bolt

成品库 finished-parts storage

产品finished product

固定式起重机 fixed base crane

固定臂fixed arm

定长式 fixed length

固定载荷fixed load

固定跨距 fixed span

固定吊具fixed spreader

固定轴距fixed wheelbase

定长吊具fixed-length spreader

Fixing

固定螺栓fixing bolt

紧固环fixture ring

夹板fishplate

工字梁 flange beam

带法兰轴承 flange bearing

弯边对焊接flanged butt weld

断续继电器 flasher delay

闪关灯 flashing light

扁平电缆 flat cable

平缓坡度 flat grade

伸直弦长 flat span

扁钢 flat steel

平顶式flat top type

挠裂 flex crack

挠度系数 flexibility factor

折臂式料粑起重机 flexible arm claw crane

软电缆 flexible cable

软管 flexible hose

挠曲寿命flexible life

软包装 flexible package

抗挠性 flexing resistance

横梁 floor girder

工艺图flow chart

流程图flow diagram/plan

折叠式扶手 folding arm rest

走道平台 foot path platform

工作平台foot platform

变动载荷fluctuating load

变化应力fluctuating stress

力臂force arm

压力管force pipe

异物foreign impurity

摩擦驱动卷扬机fraction drive hoist

双支腿龙门吊full arch gantry

构造缝 functional joint

Introduction about ZZHZ HZSP30 Concrete Spraying Machine

According to the requirements for the development of High-speed railway, ZZHZ develops HZSP30 Concrete Spraying Machine, which has been praised and welcomed by home and abroad.

The main units HZSP30 concrete spraying machine are as following:

1. Chassis Device:

Chassis of HZSP30 concrete spraying machine includes traveling and driving system, diesel engine system, steering system, braking system and carriage.

2. Working Device:

Working device of HZSP30 concrete spraying system covers concrete pump-delivery system, cantilever crane, sprayer and driver system, accelerator delivery and metering system, air compressor group, pneumatic system and centralization lubrication system.

3. Hydraulic Device:

Motor-driving system, diesel dynamic system, hydraulic system, electric controlled on-ramps, sensory parts off-ramp.

4. Electric Device:

Electric device of ZZHZ HZSP30 concrete spraying system contains electric-controlling and hydraulic system, accelerator metering and controlling system, electrical cable system, cab interfacing system, working appliance operation interfacing system, remote controlling system.

5. Basic Body:

The basic body of HZSP30 concrete spraying group adopts pour-plug type concrete pump, 6 DOF manipulator, sprayer components, double screw compressor.

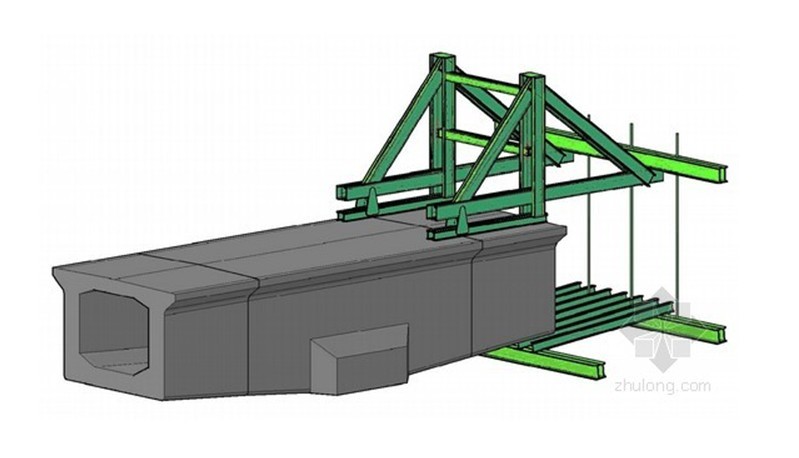

6. Boom Device:

2-phase scale and bend over available structure is reasonable, which can connect pivoting support with carriage frame, so that it is free of dead corner and can spray blind area effectively.

See more, please visit: zzhz.com

Contact: Amy

Email: zzhz114@gmail.com

Tel: 0086-371-68000000

Comparing: Bridge Crane VS Gantry Crane

Comparing: Bridge Crane VS Gantry Crane

For bridge crane and gantry crane, each crane has a bridge which extends across the crane structure from rail to rail. It sits on an end carriage that has a set of track wheels which run on a rail on either side of the building.

With a wide range, bridge cranes are always used inside factories to finish jobs. In general, they are attached to opposing factory walls and run on overhead rails. For gantry cranes, they are used in factories and outdoor storage yards such as railway and shipping storage areas. Gantry cranes have two or four upright supports, which move along two ground-based rails. The max hook height can decide the height of supports.

Bridge and gantry cranes can be classified into remote controlled, cabin controlled and pendant controlled ones. In most cases, bridge and gantry cranes are controlled by a pendant push button, which suspended from the crane structure. As to cabin controlled cranes, they have a widespread use especially when it is impossible to have a clear walkway or when the driver must be protected well. For instance, if the driver works in the steel industry, they must be kept off the extreme heat from the liquid steel carried by the cranes.

At ZZHZ we have a professional bridge crane & gantry crane team that is committed to providing the lowest prices possible and the highest quality products available. –

See more at: http://zzhz.com

Email: zzhz114@gmail.com Tel: 0086-371-68000000

Hoisting Machine: to Do’s and Don’ts about Synthetic Slings

Made from polyester, polypropylene, nylon or polyamide, synthetic slings are widely used for hoisting machines where it is vital to prevent the load from electric hazards or damage. Considering safety of hoisting machine, synthetic slings must be inspected before each use. Especially a sling is devoted itself to severe conditions, the hoisting machine operators should pay more attention to schedule inspections.

Looking for:

- Internal abrasion which is often indicated by a presence of dirt and girt or a thickening of the sling.

- Any external wear such as contusions or cuts.

- Damage to the stitching or label.

- Damage caused by chemicals, sunlight or high temperatures. The discoloration will tell you the change.

- Damage to the eyes or any end fitting or terminal attachments.

- Damage to any protective coating of the sling.

- The covering sleeve must cover the sling for the full length.

Slings must be stored:

- In a dry, clean, well ventilated place.

- Away from extreme of heat.

- Away from ultra-violet light, direct sunlight or fluorescent lights.

- Away from sources of ignition.

- Away from the possible of mechanical damage.

- Away from liquid or atmospheric chemicals.

Abandon a synthetic sling if:

- There is any damage to the sleeve or protective coating.

- The label has been removed or destroyed.

- A polyester sling comes into contact with alkaline substances.

- A nylon sling comes into contact with acid.

- A polypropylene sling cones into contact with an organic solvent such as coal tar, paint or paint stripper.

Any question or demand about hoisting or construction machines, please feel free to contact us.

Email: zzhz114@gmail.com Tel: 0086-371-68000000

Construction Machinery: How to Maintain Hydraulic System?

As for construction machinery, whether the hydraulic system in good condition is an important index. Qualified oil is fine safeguard for hydraulic system and right maintenance is its fundamental for reliability service. In general, specific operations about maintain for hydraulic system are as following:

1. To choose suitable hydraulic oil.

Hydraulic oil is playing a part of passing on pressure, lubricating, cooling and sealing, and etc. In fact, the leading cause for early malfunction phase is improper choice for hydraulic oil. Different types of hydraulic oils can’t be mixed, so that chemical reaction can be avoided.

2. To keep off solid & impurity interfusing hydraulic system.

There are a lot of precise components. Once solid impurities are making an intrusion, blocking will occur easily. Clean oil is vital for hydraulic system. Therefore, below tips should be remembered.

A. The tools for adding oil must be kept neat and we had better filter the oil at first.

B. Air and water can’t be mixed into oil because air will make it oxidize and deteriorated and water may lead hydraulic components to rusted and accelerate the abrasion.

3. To avoid rough action during operation.

Brutal handle is so inadvisable that it may cause shock load and decrease the service life of construction machinery. Do not forget to maintain it at regular intervals.

Email: zzhz114@gmail.com Tel: 0086-371-68000000

What are two methods to install simply supported concrete girders segments?

For segmental assembly beam launcher, there are two methods to install simply supported concrete girders segments. One is full span precast girder segments assembly, the other is balanced cantilever method.

What is precast girder segments assembly method?

Precast girder segments assembly method for beam launcher means to longitudinally divide girders into several sections, and prefabricate them in the factory or near to the bridge and carry them to bridge abutment, then add pre-stress to assemble all segments to the whole structure.

What is full span method to construct bridge?

Full span method means to install one whole span precast girder at one time as the beam launcher constructs bridge. Generally the full span method is suitable for bridge with span 20-50m and girder weight 30t-900t, below are concrete steps:

What is balanced cantilever method in bridge construction?

Balanced cantilever method is also called hanging basket method. It uses movable suspended scaffolding (hanging basket) to pour concrete symmetrically from two ends to their respective middle span at the same time and impose pre-stressing force.

How many bridge construction methods does ZZHZ have?

ZZHZ mainly use below methods to construct bridge.