“Made in China” Africa first cable-stayed bridge closure, many indexes rank first in the world

Morocco Grey river cable-stayed bridge is totally closed on Morocco time pm 13:40, May 6, which is contracted to build by No.6 Company of China Railway Major Bridge Engineering Group.

MoroccoGreyRiverBridge is the first stay-cabled bridge invested to build by the Kingdom of Morocco, as well as the first stay-cabled bridge in Africa. It features unique design, good-looking appearance, fluent lines but high construction difficulty. Main girder of the bridge is of steel-concrete structure, main tower adopts beautiful diamond structure which is opened gradually with an arch structure from the bottom to the top part, and divided into 4 parts in the middle and closed in one at top of tower. Called DreamBridge by natives, regarded as a national pride, the bridge is a landmark construction in Morocco.

With an overall length 951.66m, deck width 26.5m, 80 pairs symmetrical stay cables on two main towers, the bridge ranks first in the world in the aspects of calculation theory, structure and construction way.

The bridge is main project in Rabat belt freeway construction; it will not only promote development of newly urbanized areas around the capital of Morocco, but also push the development of logistics industry from Europe to Maghreb area.

Details of main girder of segments assembly launching girder

Main girder is of steel box type, made up of upper and lower layers which are connected by bolts. It has 5 sections with a total length 58m, 11.75m each for 2 sections, 11.5m each for 3 sections, featuring compact structure, high stiffness and mature producing technology.

Upper cover plate of main girder sets rails for large overhead gantry crane and 10t overhead crane, space between them will be used as walkway and their cable layout platform. Both sides of lower cover plate set longitudinal slides, longitudinal rails in the middle. Hanging longitudinal beam is set at upper flange at inside of main girder.

Both ends of main girder set upper and lower connection girders.

How many kinds of launching girders in ZZHZ are used to contruct simply supported span bridge?

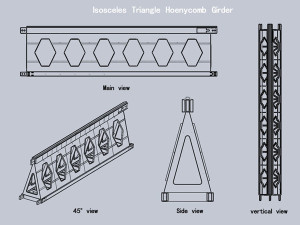

What is honeycomb type main girder of beam launcher?

Beam launcher made by ZZHZ adopts honeycomb type main girder structure which greatly reduce wind impact on main girder and improve its stiffness.

Honeycomb girder features light self-weight, high stiffness, low deflection and high wind resistance. The main longitudinal girder keeps load-bearing steel plates at two sides of box girder, removes non-load-bearing steel plates at upper and bottom parts, directly welds two sides steel plates together, replaces U-steel at bottom parts, thus the honeycomb girder structure is designed, it keeps the advantage of box girder and overcomes its shortcoming of too heavy structure.

Honeycomb girder features light self-weight, high stiffness, low deflection and high wind resistance. The main longitudinal girder keeps load-bearing steel plates at two sides of box girder, removes non-load-bearing steel plates at upper and bottom parts, directly welds two sides steel plates together, replaces U-steel at bottom parts, thus the honeycomb girder structure is designed, it keeps the advantage of box girder and overcomes its shortcoming of too heavy structure.

Many customers buy another beam launcher after purchasing and using one set, mostly because they think the main girder has high stiffness and will not distort easily.

What are working principles of launching girder?

HZPA150 launching girder construction state is whole span hanging construction

1 locating basis

Longitudinal positioning for the whole machine: relative position of front support leg and main frame does not change, as span decreases, rear support leg moves forward, centre line of support leg shall parallel with centre line of piers

Horizontal positioning for the whole machine: take center line of bridge as locating basis, the launching girder is installed symmetrically.

2 hanging construction of segments in one span

All external force in working shall be taken by front and rear support legs, which is transferred to piers and pile caps by stand column under front and rear support legs. Specific process to install girders: feed girder below the bridge—lifting—hanging—adjust segments roughly—coating epoxy resin—precise alignment—tension permanent pre-stressed steel—remove suspender—one span installation is finished.

3 longitudinal movement to cross spans

Front and support legs move by themselves to relevant position, with oil cylinder pushing force for longitudinal movement, the launching girder can realizes crossing piers, and moving forward in a horizontal curve can be adjusted by horizontal moving mechanism on front and rear support legs.

4 horizontal adjustment of launching girder

Horizontal movement flange position is reserved in front and rear legs, which can push main frame to move laterally on main girder of support legs.

3 ways to operate front and rear support legs of segments assembly beam launcher

Front and rear support legs are two main parts. Main function: support and jack the whole beam launcher, drive the beam launcher moving forward to cross spans and move laterally, move forward and backward by themselves.

There are 3 ways to operate front and rear support legs: jacking, longitudinal moving and horizontal moving.

A. jacking

Mechanical lock device is set on oil cylinder of front and rear support legs, after oil cylinder jacks them to proper position, cylinder rod protrusion shall be locked immediately with nuts and hoops, then the pump station can stop.

B. longitudinal moving of launching girder

Longitudinal moving cylinder stretches out and draws back to help realize longitudinal moving of launching girder

C. lateral moving of launching girder

Before adjusting lateral moving, lateral anchoring shall be loosened at first, then drive the lateral cylinder. After finishing the first action, loosen bolts by lateral moving device on front and rear legs, draw back the cylinder and lateral device at the same time, plug the bolts again for second action.

Safety knowledge of engineering machinery(Ⅱ)

Safety knowledge of engineering machinery(Ⅱ)

2. The main reasons of mechanical injury accidents

(1) The safe measures of maintaining and inspecting the machine are ignored.

When the maintainer repairs the machine, he does not cut off the power and set a warning guard. The switch is off due to the timing or the power is suddenly off. The worker starts to work before the machine stops completely.

(2) Lacking safe devices

Some parts are short of good protective devices, including the belt conveyor, ball mill, crane, hoist, lathe, roller machine, sand mixing machine, screw conveyor, pump, die machine and crusher.

(3)The layout of the switch is not reasonable. When the emergency appears, the machine is not stopped timely. And lots of switches are set in the same places and people may push the wrong switches to cause accidents.

(4)The machine or equipment is modified in random without complying with the safe requirements.

(5)The machine is cleared when it is still in operation.

(6)People go to the dangerous places to work.

(7)Unqualified people do some dangerous work.

Safety knowledge of engineering machinery(Ⅰ)

Safety knowledge of engineering machinery(Ⅰ)

1.Concepts relating to mechanical injury

(1)What is the mechanical injury?

The mechanical injury refers to the harm that the machine brings to people.

(2)The features of the mechanical injury.

The forms of the mechanical injury include blending, pushing, pressing, grinding and son. When people find that some people are injured by the machine, even if we stop the machine in time, the harm the machine brings to people is great due to the inertia effect of machine.

(3)The common mechanical machine injuring people

They are belt conveyor, ball mill, crane, hoist, lathe, roller machine, sand mixing machine, screw conveyor, pump, die machine, crusher, mixer, wheel grinding machine, felting material spreading machine, drum sieve and so on.

(1) The safe measures of maintaining and inspecting the machine are ignored.

When the maintainer repairs the machine, he does not cut off the power and set a warning guard. The switch is off due to the timing or the power is suddenly off. The worker starts to work before the machine stops completely.

(2) Lacking safe devices

Some parts are short of good protective devices, including the belt conveyor, ball mill, crane, hoist, lathe, roller machine, sand mixing machine, screw conveyor, pump, die machine and crusher.

How to Maintain the Bridge Building Machine

How to Maintain the Bridge Building Machine

1.The maintenance of the main components

(1) The open and closed gear painted monthly using a lubricating grease.

(2) The wire rope should be lubricated periodically and before that the pollutants should be cleared away.Whenever over 6 ropes are broken in the joints, they should be replaced instantly.

(3) The bearings must keep lubricative and be lubricated regularly. If the temperature is too high and noise too big, they should be checked carefully and if there are any damage of them, they should be replaced timely.

(4) When the thickness of wheel wear is over 15% of the original wheel, the wheels should be replaced.

2.The maintenance of the metal structure

The main girder is the main stress-bearing components. The performance,safety and the service life depend on whether the machine is well maintained.

(1) The sharp start and brake must be avoided.

(2) The welding seams among the girders should be checked, and if any one of them is found, the machine should be stopped to be welded again.

(3) If the main girder is founded to be deformed and not stable, it should be stopped and handled properly.

(4) All the metal structures should be painted twice every year. The oil stain, water and other things on the surface of the metal structure should be cleared away before the metal structure is being painted.

Effective Methods to Avoid the Engineering Mechanical Failure(Ⅲ)

Effective Methods to Avoid the Engineering Mechanical Failure(Ⅲ)

Reduce the influence of various erosion

The corrosion refers to the phenomenon of the chemical or electrochemical action between the metal surface and the surrounding medium. This corrosive effects will not only affect the normal operation of mechanical appearance of the device, but will corrode the internal mechanical parts. Things like the rain, air, chemicals and other mechanical parts go into the inside machinery through foreign channels, cracks, etc., corroding the mechanical parts inside, accelerating the mechanical wear and increasing the mechanical failure. Due to the invisible corrosive effects, they are easy to overlook, and thus cause greater harm. In use, according to the prevailing conditions of local weather and air pollution, management and operations staff should take effective measures to reduce the impact of chemical corrosion on the machinery, and the focus is to prevent the mechanical intrusion of rain and airborne chemical composition.

Zhengzhou Huazhong Construction Machinery Co., Ltd is a professional manufacturer producing many kinds of construction machinery. If you have any need, feel free to call 0371-68000000. We make sure that you will have a pleasant shopping.