Effective Methods to Avoid the Engineering Mechanical Failure(Ⅱ)

Effective Methods to Avoid the Engineering Mechanical Failure(Ⅱ)

Keep work load in the normal limit

The size and nature of the work load of construction machinery has a significant impact on the mechanical loss process. Generally, the wear of the parts is in proportion to the load increased. When the load of the parts designed to withstand is higher than the average load, the wear will increase. In addition, with the same other conditions, there will be less wear and failure in the condition of the stable load rather than the dynamic load. Tests showed that compared with the stable and unstable load, the later will increase the wear of the cylinder twice. The engine work under the condition of normal work load,has a low failure rate and long life expectancy. Instead, the failure rate of the engine with overload increases significantly, and the life will be less than the designed specifications. The wear of the machinery working with stable load is less than that working with unstable load. Generally, the life of the generator used by the engine is longer than those used by bulldozers, excavators, etc.

Effective Methods to Avoid the Engineering Mechanical Failure(Ⅰ)

Effective Methods to Avoid the Engineering Mechanical Failure(Ⅰ)

Reduce the influence of temperature

In operation, each component has its own normal temperature range. As the cooling water temperature is generally 80-90 ℃, and the temperature of hydraulic oil of the hydraulic drive system is 30-60 ℃. If it is less than or greater than this range, the wear of the parts will be accelerated, causing deterioration of the lubricating oil and the changes in material properties, and so on. For this reason, in the course of using the construction machinery:

(1)The machinery should not work with overload at low temperature to ensure the normal low-speed operation in the pre-heating stage so that the machinery can reach the required temperature before traveling or working, which should not be neglected because it was not a problem at that time;

(2) The machinery should not operate at high online casinos temperatures, the value of the operation on a variety of thermometers should be checked in the mechanical process and if any problem is found, the machinery should be immediately shut down for inspection to find and remove the fault. The machinery with reasons not found, should not continue to work without being checked.In the usual work, the working conditions of the cooling system should be checked. The water-cooled machines must be checked daily before work with cooling water added; as for air-cooled machines, the dust on the air cooling system should be regularly cleaned up to ensure the smooth flow of cooling air.

Any problem about our product, please call 0371-68000000.

The Safety Operation Specification of the Bridge Crane (Ⅲ)

The Safety Operation Specification of the Bridge Crane (Ⅲ)

8.No lifting for the following ten occasions

1)The commanding signals are not clear. Or the driver makes the commands without complying with the regulations.

2)The lifting loads exceed the ruled weight.

3)The lifting loads are not bound firmly.

4)There are people on the lifting loads.

5)The safety devices are not complete. Or one device fails to operate well.

6)The aircraft is buried under the ground.

7)The light is dark and not clear.

8)The objects with corners and edges without corresponding cutting prevention measures.

9)The aircraft is being pulled slant.

10)The steel ladle is too full.

The Safety Operation Specification of the Bridge Crane (Ⅱ)

The Safety Operation Specification of the Bridge Crane (Ⅱ)

3.The duty of the driver

1)The driver must confirm to the pass down system and try his best to do his work well.

2)The driver must check the crane completely, after which the driver can put the crane into test without load for several times. All the switches should be checked to ensure their safety.

4. In the following situations, the driver should send the warning signals

1)After the crane is started, the driver starts to drive it.

2)One crane is close Big range of marijuana cocaine detox kits kits that are available in our online shop would let you clean your body from marijuana toxins as well as to pass the marijuana drug test without complications. to other cranes in the same level.

3)The lifting loads are being placed down.

4)The lifting loads come close to the staff.

5)The crane operates on the lifting channel.

5.The limiter should not serve as the tool to stop the machine.

6.The lifting loads are not allowed to stay or pass above the staff and they should be lifted along the safe lifting channels.

7. When the magnetic chuck or the grab crane is being operated, no one is allowed to work under the lifting loads. And the danger zone should be underlined and equipped with a warning board to attract people’s attention.

The Safety Operation Specification of the Bridge Crane (Ⅰ)

The Safety Operation Specification of the Bridge Crane (Ⅰ)

1.The basic requirements for the driver

1)Stability. When the driver operates the crane, he must ensure that the lift and brake must be stable and that the hook, lifting loads and the lifting appliance should not shake.

2)Accuracy. Based on the stable operation, the hook, lifting loads and the lifting appliance should be placed in the designated places.

3)Rapidity. Based on the above factors, the corresponding mechanisms should be coordinated to ensure that the crane can work continuously to increase the efficiency.

4)Safety. We should ensure that the crane works normally. During the operation, we must comply with the safety operation specification to avoid the occurrence of the accidents.

5)Reasonability. On the basis of understanding the performance of the crane, according to the detailed state of the lifting loads, we must control the machine reasonably.

2. The general

1) The worker aging 18 should have a medical test and should be proved qualified. They should receive professional train of operating the crane and the safety education. Under the lead of the experienced worker for a year, after they gain the operation certificate of special trade, they can operate the crane alone.

2) The driver should have a knowledge of all the mechanism, performance, usage of the crane and the common knowledge of the electric equipment.

3) The driver is not allowed to smoke, eat things or read books.

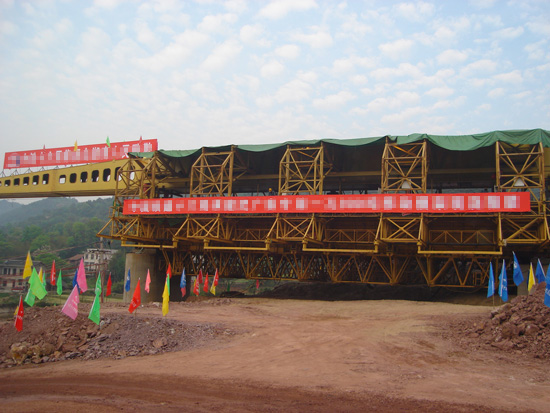

The Working Precautions of the Bridge Building Crane

The Working Precautions of the Bridge Building Crane

With all of those things meeting the design requirements, the bridge building crane is allowed to walk longitudinally.

Before each girder is in place, the temporary support should be in both ends to make the large girder keep vertical and stable to avoid overturn and displacement. After the second girder is ready, the reinforcing steel of the two ends of the insulating steel of cross beam should be immediately welded except the temporary support to strengthen the stability.

Before the bridge-erecting crane walks longitudinally, the weld of the insulating steel of cross beam should be finished and the concrete should be placed in the insulating steel of cross beam.

The transvrsal walking rails of the front, middle and back triggers should be paralleled and the certain distances among them should be kept.

When there are the upper and lower longitudinal slopes, the preventing slipping measures should be taken when the bridge erecting crane displaces longitudinally.

The bridge erecting crane must lift objects to go on a run test after its’ assembly is finished. Alternatively, it can go on a run test with the concrete girder, after which the bridge-erecting crane can be in place and begin the assembly.

Only with everything ready, the bridge-erecting crane is allowed to walk longitudinally, which is asked to be finished in one time without stop in the middle way.

The Maintenance and Protection of Bridge Building Crane

The Maintenance and Protection of Bridge Building Crane

1.The brake of the lifting mechanism should be checked every day and the brake of the operating mechanism every 2 or 3 days. When they are being checked, whether the movements of each brake system is flexible should be paid attention to.The segments should be fit on the brake wheel without physical damage. The brake of the lifting mechanism must ensure 1.25 times of the rated capacity and the damaged sunny canopy should be replaced timely.

The bearing for drive of the traveling box of the crane and the trolley should be pointed into albany grease every 2 years.

2.The maintenance of the electrical equipment

To ensure the safe operation of the crane, the reasons and solutions of various accidents of the bridge erecting machine should be familiar with.

The electrical equipment including the resistor, control panel and contactor etc., should be kept clear, and the dust as well as the dirt outside or inside the electrical equipment should be cleared away to prevent current leakage, breakdown, short circuit and so on.

Whether the motor rotor slip line and brush contact is in good order should be checked frequently.

Whether the sound produced by the motor, electromagnet, electromagnetic relay and switch is normal.

Whether the cam controller and contactor appear the sign of burning, if any, they should be replaced or reused after they are being polished with emery cloth.

When the outside conditions are bad, the motor, electric wire as well as the insulation resistance should be checked regularly.

The rust and dirt on the slide rail must be cleared away timely.

The inspection whether the installation of each electrical equipment is fixed and the movable parts move flexible should be made frequently to exclude the abnormal factors.

The Technical Requirements of the Overhead Crane

The Technical Requirements of the Overhead Crane

1. The Installment of the motor and the reducer: a moderate number of the grease should be applied on the rear leg group. And the motor and the reducer should be fixed on the rear leg group.

2. The installment of the wheel group of the overhead crane: the wheel group of the motor and reducer should be in place. The beam of the overhead crane should be lifted on the wheel group of the overhead crane. And they should be connected to the pin roll and the bolts.

3. The installment of the lifting trolley and the head block assembly: the lifting trolley and the head block assembly should be placed on the beam of the overhead crane. The lifting trolley is above the head block assembly.

4. The installment of the hoist: the hoist should be placed on the base plate.

5. The placement of the overhead crane: the well completed overhead crane should be placed on the rail of the main beam.

6. The installment of the movable pulley and hangers: the rope of the hoist should be slack but be winded with the steel wire rope, which should be fixed with cable loop. The hangers should be connected to the movable pulley.

The Technical Requirements of the Rear Leg

The Technical Requirements of the Rear Leg

1. The installment of the pump station: the tread plate should be placed inside the main beam support beside the rear leg, serving as a working platform. The oil pump should be placed on the working platform and fixed firmly with the iron wire. And then, the liquid oil should be poured into the oil pump.

2. The installment of the jack: the body of the jack should be fixed on the lifting lug of the main beam.

3. The installment of the motor and reducer: a moderate number of the grease should be applied on the rear leg group. And the motor and the reducer should be fixed on the rear leg group.

4. The installment of the bracket: the bracket should be covered on the telescopic tube. And then the racket and leg should be installed on the main beam with the bolts. The telescopic tubes should be connected with the jack.

5. The installment of the rear leg group: the rear leg group should be placed on the rail of the girder transport in working state.

6. The installment of the rear beam: the telescopic tube of the rear leg falls off. The telescopic tube of the rear leg should be connected with the rear beam.

The technical parameters of the HZQY900B bridge girder launcher integrating carrying and erecting

The technical parameters of the HZQY900B bridge girder launcher integrating carrying and erecting

Total weight: about 735t

Out dimension: 98.4×9.1×7m

Rated lifting capacity: 900t(not including lifting appliance)

Climbing ability: 30‰

Min. turning radius 155m

Min. curved radius 2000m

Max. longitudinal slope 30‰

Applicable height ≤2000m

Working temperature -20°C / +50°C

Max. wind force in working state grade 6

Wind force off working state grade 11

Using class U0

load states Q3

working class of the whole machine A3