What is the preparation work to install HZQ30/80 bridge crane?

The bridge girder launcher is of heavy bridge crane, to ensure its normal work, it is necessary to operate the machine in accordance with operation instruction manual and current related rules.

What are special attention to HZQ30/80 bridge girder launcher?

1. Horizontal movement

a. As an important front part support of the bridge girder launcher, front support leg uses transverse movement gear box and transverse sliding rail to make the whole machine move transversely

b. As an important rear part support, middle support leg uses transverse movement gear box and transverse sliding rail to make the whole machine move transversely

c. Transverse moving mechanism at upper part of the lifting trolley can make the trolley move transversely along transverse sliding beam and rail

2. Install the boundary beam

The trolley lifts the girder to move transversely, distance between lifting steel wire and the bottom part of main girder should be about50mm

The whole machine moves transversely to put the boundary beam in the right place at a time. There is no need for the bridge girder launcher to move out of the abutment, quite safe, reliable and convenient.

3. Safety control mechanism

a. Electrical safety control

Leakage protection device for main power switch; launcher travelling emergency stop button; lifting travel limit(highest), launcher moving limit, trolley moving limit; lifting loader limiter; lifting trolley parking locking device; launcher clipping rail device

b. Electrical system protection device

Overload, overcurrent, short-circuit protection, monitoring indicator and interlocking device; overvoltage, undervoltage protection; mechanical, electrical interlocking institution (avoid misoperation)

Limit switch

Launcher moving limit, trolley moving limit, lifting travel limit (highest)

Overload

Lifting load limiter

What is Main Structure of HZQ30/80 Launching Gantry?

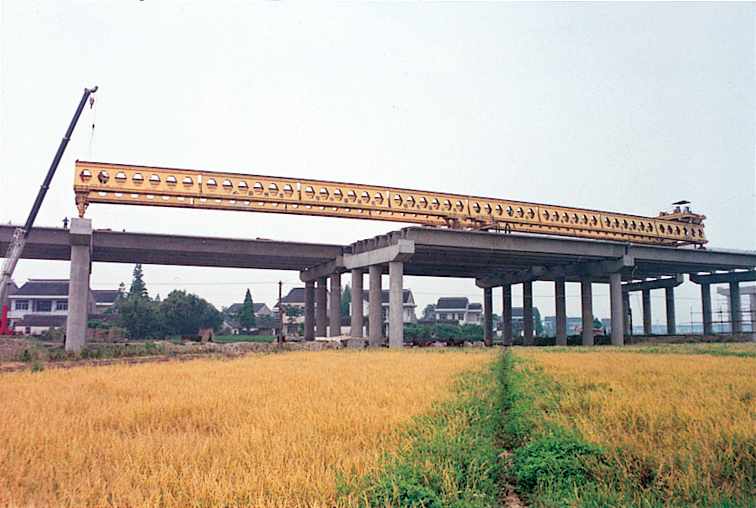

The bridge girder launching gantry is made up of main girder, trolley, front support, middle support, rear support, electrical system and hydraulic system

1. Main girder

Main girder is made up of two parts: triangle honeycomb girder at left and triangle honeycomb girder at right. Each part has a total length of about50m. section to section connected by pin roll. The two parts main girders are connected by middle hoop beam and connection framework

2. Trolley

Made up of longitudinal moving gear box, heightening section, transverse moving beam and rail, transverse moving gearbox, trolley rack, winch, pulley block, hanging beam and connection framework

Trolley is the lifting mechanism. lower longitudinal moving mechanism makes trolley moves on rail on main girder; upper transverse moving mechanism makes trolley move on lateral sliding beam and rail; winch can lift the precast girder; above three parts and trolley steel structure as an unity finish lifting, moving, dropping precast girder and installing boundary girder as well as lifting small articles to front abutment; matched hanging beam has a wide use range to lift T type girder as well as box girder

3. Support

Front, middle, rear support and rear bracket. Front support and rear bracket have telescopic functions

Front support consists of bracket, internal sleeve, outer sleeve, connection beam, rotating connector, transverse moving gearbox, transverse sliding rail, front connection frame, fixing device, rail clamping device, hydro-cylinder and pin shaft.

Middle support: as a rear-end support when bridge girder launcher begins to install a girder, it is made up of roller institution, core tray, half curved beam, driving gearbox, driven gearbox, fixing device, transverse sliding rail and pin shaft.

Rear support is located in rear part of main longitudinal girder, made up of bracket, internal sleeve and outer sleeve. It is a rear-end support of bridge construction machine and a support for replacing support leg when moving from one pier to next pier.

Installed between middle support and rear support, rear bracket consists of hanging mechanism, roller mechanism, internal sleeve, outer sleeve, hydro-cylinder and pin shaft. As a rear end support to make main girder move forward when bridge construction machine installs a girder, the rear bracket could move at bottom of main girder with hanging mechanism, drive main girder to move forwards smoothly with roller mechanism. The internal and external sleeves can adjust the height of rear bracket to better adapt to crossing piers on slope bridge.

4. Hydraulic system

Made up of two groups of independent hydraulic stations on rear support leg and rear bracket , multiple directional control valve, cylinder and oil way. Located at the bottom of main girder, two hydraulic stations provide power for telescopic support legs

5.?Electrical system

Made up of motor and control cabinet with power about 75kw,? connected by cable, guide line and motor. Two control cabinets are fixed separately on rear parts of main longitudinal girder and lifting trolley. Control cabinet on trolley controls movement of trolley motor, while that on longitudinal girder controls crane?s longitudinal and transverse movement.

What is the brief introduction of HZQ30-80 bridge girder launcher?

(1). technical solution

1. bridge girder launcher program

After researching and analyzing current highway bridge girder launcher at home and abroad, combining with our successful experience, we develop and produce the walking type bridge girder launcher according to practical situation.

What customer can get from ZZHZ as purchasing a honeycomb girder launching gantry?

Firstly, you can enjoy perfect service: 1 year quality warranty. When there is a problem, we will arrive at your place to help you solve it as soon as possible. We also guide you to install and commission the machine with free charge, train your workers with free charge

- honeycomb girder launching gantry

Which is more economical, movable support system or bridge girder launcher?

Movable support system is a kind of construction machinery to install bridge girders by way of cast-in-place with its own formwork, supported by box girder.

Bridge girder launcher realizes bridge construction if the girder carrier transports the prefabricated concrete girder to the rear part of the launcher.

Difference between movable support system and bridge girder launcher

- Without prefabricating concrete girder in the precast girder yard, the movable support system adopts cast-in-place and field maintenance. Averagely it finishes one piece of girder every 12 days. While for the bridge girder launcher, it needs to prefabricate concrete girder, then transport them to be installed on the bridge floor

- The movable support system has a longer cycle to finish the project but with low investment and high benefit; the bridge girder launcher with a short completion time but high investment

- With low investment and short preparation time, the movable support system can be fast put into use. While the bridge girder launcher needs a long time to prepare for other equipments such as girder carrier and gantry crane.

- With less land occupation, the material cost of the movable support system is relatively low.

- The movable support system is widely used in the mountain area that can not build large-sized precast girder yard, while the bridge girder launcher is popular in large-sized precast girder yard

To sum up, it depends on the practical situation. But generally, the movable support system is more economical and more suitable for constrictive economy environment at present and in the future.

What is Difference between Bridge Girder Launcher and Movable Support System

1. Bridge girder launcher is a equipment that helps put prefabricated precast girders on prefabricated piers. It lifts the precast girder slabs, transports them to specific location and drops them, so it is included in cranes. But there is a strict demand on the bridge girder launcher, because it needs to move on the precast girders (longitudinal movement of the bridge girder launcher).

?Three kinds of bridge girder launcher:

a. Highway bridge girder launcher

b. General railway bridge girder launcher

c. Passenger railway special line bridge girder launcher

2. Movable support system bridge making machine is a construction machinery of cast-in-place segmental prestressed concrete box girder with its own template, supported by box girder structure. It can finish a series construction from moving supports to casting mold.

Main features: high construction quality, convenient handling and low cost

In foreign countries, it has been widely used in construction of continuous beam in highway bridge and railway bridge projects, is an advanced construction way.

In domestic market, it begins to be used in highway and railway special line for passenger

Main parts: support mechanism, supporting truss girders, internal/external formwork and lifting mechanism of main girder

How does the Bridge Girder Launcher Construct Bridge?

With the development of our national economy, the construction of high speed railway reaches unprecedented upsurge. For 10 years, ZZHZ has been involved in manufacturing construction machinery and hoisting machinery. Therein, bridge girder launcher and gantry crane are widely used in high speed railway construction, being awarded the national patent. Featuring reasonable design, convenient installation and dismounting, especially high safety, they are highly praised by our customers and make great contribution to safe construction of high speed railway. Construction project of Beijing-Shanghai high speed railway will be one of the biggest projects.

What is Brief Introduction of Launching Gantry for Carrying and Installing Girder

ZZHZ is a professional manufacturer of hoisting machinery such as gantry crane and bridge girder launching gantry which are widely used in highway construction

Compared with box girder, honeycomb girder launching gantry made by ZZHZ features low centre of gravity, light weight, high safety and high wind resistance. Compared with truss girder, it has a large welding surface with uniform stress; when the truss girder bears force, U-steel welding points will be load-bearing contact points which will deform terribly as bearing load. So honeycomb girder has a low deflection, high stiffness. 6 steel pins connect two longitudinal main girders, knock them into two main girders, the installation is finished, featuring short time and uniform force. Usually, the installation of the whole launching gantry can be finished in one week.

A middle support leg and a round girder are added on the bridge girder launching gantry integrating carrying and installing girder developed by ZZHZ. Steps to install girders:

1. The machine finishes installation on the roadbed, then moves forward from one pier to next pier.

2. Support the front part of the machine, knock out the connection pins at the middle part, disconnect two parts of launcher, the rear part can carry girders to the precast yard.

3. The rear part lifts the precast girder and moves to the abutment

4. Connect it simply with the front part of the bridge girder launching gantry by rail splints and bolts, two lifting trolleys lift the precast girder moving to the front part and put down the girder slowly

5. When install the boundary beams, put the precast beam in the place of middle beam, using one side single girder to bear load, the hanging gallows and trolley lift the precast girder to move horizontally to the right place.

Generally with different terrain in different worksites, we choose different construction methods.

Featuring multifunction, high efficiency and low cost, the bridge girder launching gantry integrating carrying and installing girders makes a large contribution to the national road construction.

What are factors to cause a bridge girder launching gantry accident?

As a professional manufacturer and seller of bridge girder launching gantry in China, ZZHZ has witnessed many tragedies: devastating accidents caused by the derail and overturn of the bridge girder launcher. Once it happens, the repair will not only cost a long time and a lot of money, but seriously affect the progress of bridge construction and rail construction. With a rapid development of high speed railway, bridge girder launcher will be used more frequently, if there happens an accident, there will have bigger losses and casualties.