The main technical parameters of the HZQ500B bridge building crane

The main technical parameters of the HZQ500B bridge building crane

1)Rated lifting capacity 500t

2)Applicable girder shape box girder of equal span or changing span with double line of 25m or 30m

3)Lifting speed of the trolley 0-0.3m/min(with load)

4)lifting height 7m

5)Horizontal fine-turning speed and distance of the trolley 0-0.5m/min and ±200mm respectively

6)Longitudinal moving speed of the trolley 0-3m/min(with load)0-6m/min(without load)

7)Lifting method of the girder lifting objects with four points with three points balanced

8)Girder bridging method cooperate with the girder transport

9)Girder bridging method moving and shifting to pass the piers with shifting speed of 0-3m/min

10) Min applicable skew bridge radius Rmin≥500m

11)Operating method in the operating room

12)Applicable longitudinal slope 30‰

13)Applicable working temperature -20℃~50℃

14)Applicable wind level grade 6(working state) grade 11(off working state)

15)Rated lifting capacity of the trolley 250t

16)Working performance taking 8h to bridge 2 pieces of whole girder (haul distance of 8km)

17)Out dimension 63.5×16×11.9m

18)Power 300kW

19)Total weight 300t

The Bridge Building Process of the Bridge Erecting Crane(Ⅱ)

The Bridge Building Process of the Bridge Erecting Crane(Ⅱ)

3.Lift the beam

1)Before any operation of lifting the beam, at least one test should be went on. That is to say, withe the completion of binding the beam, the test of braking should be went on 2-3 times.Then, a few beams are lifted and whether the steel rope are quit and the iron tiles move or jump off should be checked. Only after all of this are checked, can the formal operation start.

2)Lifting the beam should be in the same step with the hoist,both of which bear even stress. The overload of the hoist and the fierce shake of the beam body should be avoid.

3)The beam should be kept balance when it is being lifted, moved and placed. If you find any tilt by your eyes, it should be corrected immediately. Sometimes, a little tilt is allowed but not too much.

4)The beam should be move on the high level.

5)When the beam is moved, the professional persons should inspect the moving state of the beam in the pier platform. Especially when the beam is to in place, the inspecting persons, commanders as well as drivers should be cautious and highly concentrated and corporate with each other.

6)The bridge erecting crane is not allowed to overload.

4.Place the beam

1)When the beam is being placed, responding measures should be taken to prevent the occurrence of accidents.

2)When the beam is being placed,the chain block should be in the front and some measures should be taken. And the chain block must be hung in the firmly.

3)When the beam is 200-300mm to the bearer, the beam can be placed continually after the bearer and shogging equipment are in place.

4)When the beam is to be in place, the two jacks in one end should be in the same step to prevent the accidents caused by the slaying beam.

5)When the bridge erecting crane is swaying, there should be professional persons to inspect the trolley.After the beam is in place, the trolley should be fixed with wheel stopper to prevent the trolley from sliding.

The Bridge Building Process of the Bridge Erecting Crane(Ⅰ)

The Bridge Building Process of the Bridge Erecting Crane(Ⅰ)

1.Feed the beam

1)Before the beam going into the bridge erecting crane, whether there are obstacles influencing the advancing of the beam in the whole machine and whether the beam capstone are too high influencing feeding the beam should be checked.

2)Before feeding the beam, the back support of the bridge erecting crane should be checked to avoid the big sinkage when the machine feed the beam.

3)When the beam is being transported, there should be personnel inspecting the bearer to prevent the collision with the whole machine. The girder transport should be run by professional persons.

4)When the beam is being transported,no person is allowed to go with the beam in the end of the beam or stand on the scaffold floor to avoid the wounding caused by the objects falling from the top of the beam.

5)When the beam is being transported,the girder transport should be pushed in slowly.And when the beam is being pushed, there should be professional persons to inspect it to prevent the body of the beam or the girder transport collide with the whole machine.

2.Bind the beam

1)When the beam is being bound, the iron tile should be fixed and symmetrical to make the steel rope in the middle. And whether the steel rope is knotted, torsional or connected with the rod should be checked.

2)The distance from the two lifting points to the points of the beam should be equal to prevent the occurrence of overload caused by the uneven stress born by the hoist.

3)The jack line used to bind the bear usually should be kept vertical.

The Use of the Special Girder Span

The Use of the Special Girder Span

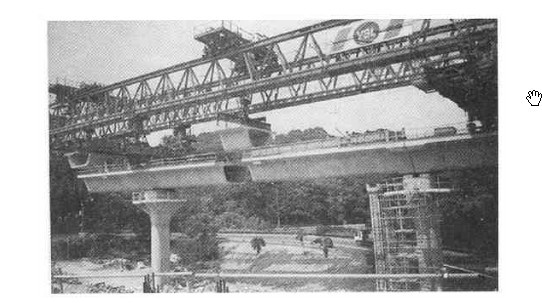

In the process of bridge erecting, there are usually special girder span including uphill girder, downhill girder, curing span etc. For this, our company develops the HZQ series bridge erecting cranes. Now take the HZQ40-140 walking type bridge girder launcher as an example.

1.The erection of the first supportbar

When the first supportbar is being erected, the middle trigger usually is on the bridge abutment and the basis of the transverse rail of the middle trigger must be solid to prevent the occurrence of accidents caused by the sink of the bridge erecting crane; before the longitudinal traveling of the front trigger, the height of the front trigger must be adjusted properly to make it in place successfully; before the bridge erecting crane travels longitudinally, everything should be checked to avoid any accidents.

The bridge erecting crane is just put into use when the first supportbar is being erected; therefore, the safe instead of speed concerns most.

2.The erection of the last support bar

When the machine erects the last support bar, the opposition of it is the bridge abutment and the front trigger must be travel on the bridge abutment; hence, the height must be decreased. The machine is equipped with chassis2 specially used for the front trigger, the middle part of which can be disassembled, and then the chassis2 and core plate are connected; finally, the chassis2 and traveling wheel box are connected.

The Assembling Steps of the Bridge Building Crane

The Assembling Steps of the Bridge Building Crane

Step 1: the sliding rail

1.The placement of the sleeper: the sleepers should be placed horizontally on the head of the bridge or the precast girder. The distance between the two sleepers is about half meters, and the sleepers should be horizontal, forming a straight line and paralleling with the bridge pier.

2.The placement of the sliding rail: each segment of the sliding rail should be placed on the sleepers with the mobile crane or other lifting equipment.

3.Ultra flat: the sliding rail should be flatted with the level gauge.

4.The support: If there is any gap or unfirm place, then it should be fitted firmly with the steel panel.

Especially, the two points of the sliding rail. The technical and safe requirements of this step:

(1)The horizontal lift and package should be horizontal. And no one is allowed to stand under the hook in the process of assembly.

(2)The sleepers under the sliding rail must be firm to avoid that the rail rolls over and injures people.

Key Tips of the Moving forward and Lifting Girders of the Bridge Building Crane

Key Tips of the Moving forward and Lifting Girders of the Bridge Building Crane

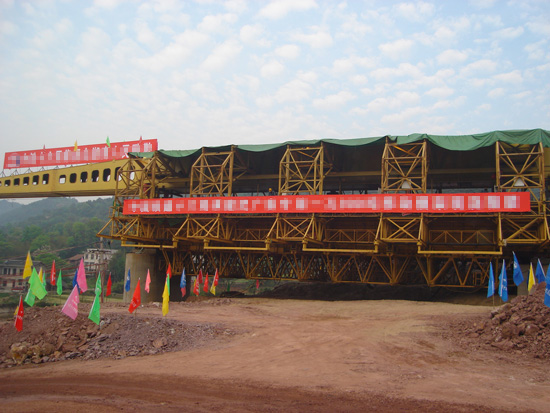

The bridge building crane for high speed railway uses full span method to construct bridge with span 20m,24m and 32m, whole span girder weight 450t-900t, it is specially designed and made by ZZHZ

1. The moving forward and lifting girders of the bridge building crane need to be guided by the professional persons. The staffs should be ready and observe the situations closely. If any problems are found, the staffs should report them without delay. Before the bridge erecting crane lifts the first girder, the test should be conducted in the back of the bridge building crane. Whether the brake of the hoist is in good state should be checked and the T girder vertical be checked. After that, the bridge build crane can start to work.

2. When the bridge building crane moves forward, each system of the crane should be checked carefully.

3. When the bridge building crane lifts girder, each leg of the bridge building crane should be fixed firmly with the steel wire rope to avoid the slant of the legs. The two hoists should be in the same step when they are pulled longitudinally. They cannot be stopped if there are no special situations to avoid that the T girder shakes due to the inertia.

The Gantry Crane Produced by Zhengzhou Huazhong Construction Machinery Co., Ltd——the Permanent Choice of the Customers

The Gantry Crane Produced by Zhengzhou Huazhong Construction Machinery Co., Ltd——the Permanent Choice of the Customers

In recent years, adhering to the marketing strategy that “Value concerns most”, Zhengzhou Huazhong Construction Machinery Co., Ltd actively expands the international and national markets. Therefore, the market of it is more and more large. Recently, two sets of MEHZ(50+50)t gantry crane are transported to Indonesia. This is the second time that we corporate with the customers from Indonesia in 2014.

Along with the construction of the international marketing net, the international market becomes larger and the brand of Zhengzhou Huazhong Construction Machinery Co., Ltd will reach the international market.

Indonesia is located in the southeast of Asia. It is the second country in Asia that owns extensive territories; the fourth country in the aspect of population; also, one member of the Asia Pacific Economic Cooperation. It is rich in natural materials, enjoying the reputation of tropical value island. The rapid increase of the population brings in more need for the infrastructure. As a result, the need for the strength of the construction is larger. As the main equipment in the infrastructure construction, the hoisting machinery from Zhengzhou Huazhong Construction Machinery Co., Ltd become more popular in Indonesia.

The Assembly of the Main Beam of the Bridge Building Crane

The Assembly of the Main Beam of the Bridge Building Crane

The assemble of the main beam

1.The placing of the front part of the beam: the sleeper ground beam that should be the same height with the middle supporter. The front part of the beam should be placed on the middle supporter or sleeper.

2.Assemble the beam in order:Another group of the sleeper should be set. Two pieces of the beam should be connected with the pins. Then the former group should be removed to set another group of sleepers, which should be repeated to assemble each beam in order.

The safe and technical requirements of this step:

1.The main beam is the most import part of the bridge building crane. Each piece of the beam is about 7.5t. The two ends of the main beam should be lifted by the steel wire rope in balance to avoid the overturn of the main beam.

2.The sleepers should be level. The base should be wider than the main beam.

The Problems That Cannot Be Ignored When the Bridge Building Crane Installing Girders(Ⅱ)

The Problems That Cannot Be Ignored When the Bridge Building Crane Installing Girders(Ⅱ)

5. When the girders are being installed, they should be moved through a crowbar to put it in the right place. No one is allowed to move the girder with its own hands. After the large girder in in place, it should be supported immediately and connected horizontally to ensure the stability of the large girder.

6. When the girders are being transported, they should be firmly bind to avoid the slant and the flat car bearing a balanced stress. The speed of the flat car should be even and slow. And the state of the girder on the flat car should be paid attention to in any moment.

7. The obstacles on and under the girders should be cleared away before the girders are being transported to avoid the accidents that the obstacles fall off the girder and cause injuries. In the process of the crane lifting objects, no one is allowed to stay under the objects being lifted. The flat car should be placed firmly before the girders are being placed down. One end of the main girder should be placed first and then the other.

The bridge building cranes manufactured by Zhengzhou Huazhong Construction Machinery Co, Ltd include the bridge building crane for highway and railway, HZQ series honeycomb girder launching gantry, HZQ series of launching gantry integrating carrying and erecting, bridge building crane for tunnels and walking bridge building cranes, which can meet all the needs of customers. If you have any need, please contact 0371-68000180 for more details.

The Problems That Cannot Be Ignored When the Bridge Building Crane Installing Girders(Ⅰ)

The Problems That Cannot Be Ignored When the Bridge Building Crane Installing Girders(Ⅰ)

The current bridge girders are usually very heavy. When they are being installed, the relevant requirements should be complied with to ensure that the girders can be installed safely.

1.Before the bridge girders are being lifted, the obstacles around the big girders should be cleared away. When the bridge girders are being lifted, one end of them should be lifted first and then the other end. Before they are fully from the ground, the two ends of them should not be lifted in the same time.

2.Whether there are obstacles on the track should be checked before the large girders are being transported longitudinally and horizontally. The staffs are not allowed to stay on the track. The broken or abrasive steel wire ropes are not allowed to put into use.

3.The road base of the girder transport should be wide and level enough. The rail should be level and straight. The sleepers should be firm. The connecting parts of the rail should not be loose.

4.There should be special people to command the transport. The contacting and communicating goods should be all in ready. In addition, the signal should be clear.